Cationic Polyacrylamide Powder CPAM in Fengbai

- CAS No: 9003-05-8

- HS Code: 39069010

- MF: (C3H5NO)n

Cationic polyacrylamide(CPAM) is a linear polymer compound. Because it has a variety of active groups, it can interact with and adsorb many substances to form hydrogen bonds. Cationic polyacrylamide has clarification and purification, sedimentation promotion, filtration promotion, thickening and other functions. So it can fully meet the requirements in waste liquid treatment, sludge concentration and dewatering, beneficiation, coal washing, papermaking, etc. Cationic PAM is suitable for wastewater treatment with high organic colloid content, especially suitable for the dehydration treatment of municipal sewage, municipal sludge and other industrial sludge.

| Item | CPAM |

| Solid Content ,(%) | ≥90 |

| Molecular Weight, (million) | 8~12 million |

| Hydrolyzing degree ,(%) | / |

| Ion degree,(%) | 10~60 |

| Ion content | / |

| Effective pH value | 1.0~14.0 |

| Dissolving time(minutes) | 40~60 |

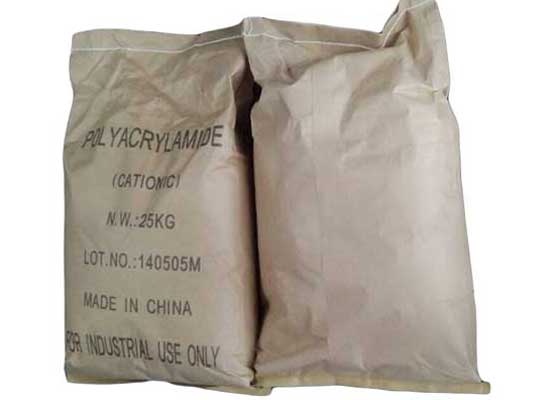

| Packing | Net 25kg / paper bag with inner plastic bag |

Inquiry Us for Quotation Here

Leave your requirements in detail here(including the specifications, package, quantity, country, etc.), we will reply you quickly.

SEND US EMAILGET PRICE NOWHow to Use Cationic PAM Powder

- Powdery cationic polyacrylamide is often used in organic wastewater. Cationic polyacrylamide flocculant can flocculate and settle the negatively charged suspended particles in the sewage. According to the cationic acidic or alkaline medium in the flocculation device, it it extremely effectively to quickly calrify sewage by relying on the positive electricity.

- For the treatment of domestic sewage and organic waste water, CPAM powder presents positive electricity in a complex or alkaline medium, so that it can flocculate and settle the sewage with negatively charged suspended particles in the sewage, which is very effective for clarification. For the treatment of grain alcohol wastewater, papermaking wastewater, municipal sewage treatment plant wastewater, beer wastewater, monosodium glutamate factory wastewater, sugar wastewater, wastewater with high organic content, feed wastewater, textile printing and dyeing wastewater, the effect of using cationic polyacrylamide is several times or tens of times higher than using anionic, non-ionic polyacrylamide or inorganic salts. For that this kind of waste water is generally negatively charged.

- The CPAM flocculant is used for the treatment of tap water with river water as the water source. The dosage is small, the effect is good and the cost is low, especially when combined with inorganic flocculants, the effect will be much better.

- In papermaking, it can be used as a reinforcing agent and other auxiliary agents. It can also improve the retention rate of fillers and pigments, as well as the strength of paper.

- Used as a mud treatment agent in the oilfield development process, a selective water plugging agent and water injection thickening agent.

- In the textile industry, it is used as a sizing agent to make the slurry performance stable, less sizing, low rate of fabric breakage, and smooth fabric surface.

- The size of the floc. Too small flocs will affect the speed of drainage, too large flocs will restrict more water and reduce the degree of mud biscuit. By selecting the molecular weight of cationic polyacrylamide powder, the size of the flocs can be adjusted.

- Sludge characteristics. According to the different main components contained in sludge, sludge can be divided into organic sludge and inorganic sludge. Generally speaking, cationic polyacrylamide is used to treat organic sludge, and anionic polyacrylamide is used to treat inorganic sludge. When the solid content of the mud is high, the amount of PAM powder is usually larger.

- Floc strength. The floc should be stable and not broken under shearing action. The molecular weight of polyacrylamide or the selection of appropriate molecular structure can help improve the stability of the flocculation.

- The ionicity of polyacrylamide. For dewatered sludge, flocculants with different ionicity can be tested to select the best and appropriate polyacrylamide, which can obtain the best flocculant effect, minimize the dosage and save cost.

- The solubility of polyacrylamide. The flocculation function can be fully exerted only when it is dissolved well. Sometimes it is necessary to speed up the dissolution rate. At this time, the concentration of the polyacrylamide solution can be adjusted appropriately.